The evolution of jewelry design and jewelry manufacturing is never complete, but in today’s world, we have reached a level of achievement so far beyond the humble beginnings of jewelry, it’s difficult not to marvel at where technology has brought us. Jewelers have gone from designing on paper and carving models by hand, to designing three dimensionally in a computer and 3D printing jewelry.

In recent years, one of the biggest developments jewelry manufacturing has been CAD, computer aided design. CAD has been used by architects, engineers, landscapers, and automotive designers. Today, we are seeing a growing trend of CAD for jewelry design. There are many different CAD programs and a variety of ways to design in them, so here is an overview of what computer aided design actually is and how it can help your business thrive.

What is CAD?

Prior to any kind of CAD for jewelry design software, the development of jewelry manufacturing prototypes was done manually. Tedious, time consuming, and expensive, designs were often laden with imperfections and had to be consistently redesigned through trial and error.

Computer aided design software eliminates most creation errors, as it is used to draft, modify, and optimize a specific design on the computer before printing a tangible model. There are specific CAD for jewelry design programs with certain design elements already implemented within them, such as setting designs, total weights, and gemstone shapes. With a CAD program you can design a jewelry prototype in two or three dimensions and then use the resultant file to 3D print a piece.

CAD in 2D

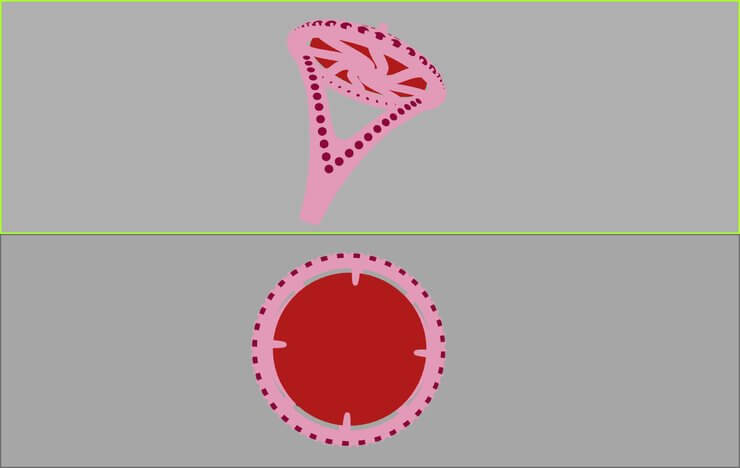

While there are 2D design softwares, like Photoshop, these are different from 2D CAD softwares. Designing in two dimensions, both for CAD and other, simpler design platforms, is like a virtual drawing board. You’re using palettes and writing tools to design in the same way you would draw an image. The main difference between the two is that CAD offers flexibility through manipulation elements.

In a CAD program, lines aren’t fixed—they can be adjusted, moved, twisted, and scaled. Better yet, no matter how you readjust the scale of a piece, everything will always be redrawn in perfect resolution. Most efficient, the files created by 2D CAD for jewelry design are also directly compatible with other applications, such as laser engraving and industrial cutting tools. This makes jewelry manufacturing much cheaper and easier.

CAD in 3D

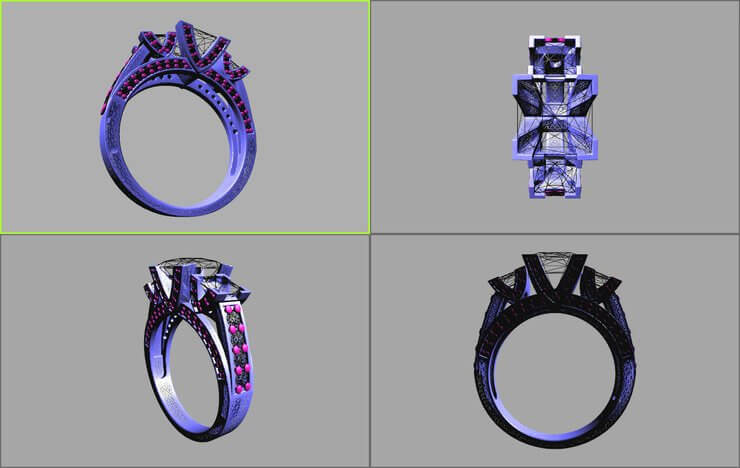

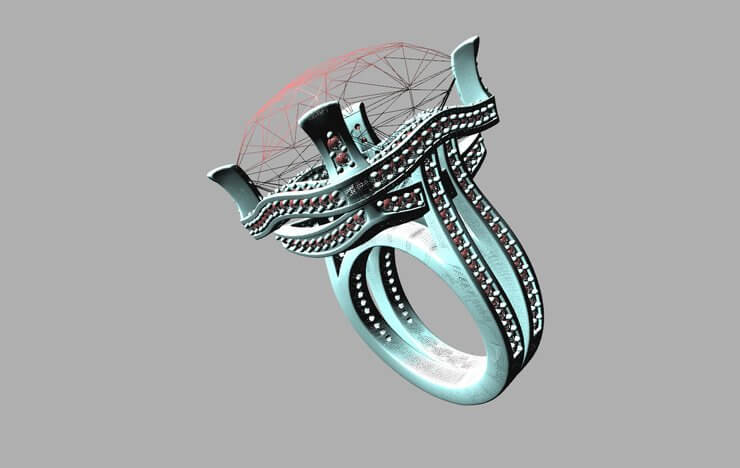

Conceptually, 3D CAD is the digital equivalent of fabricating tools and a wax carving kit. Instead of simply making designs on the screen, you’re actually building a piece to your exact specifications. The end result of a CAD-made piece can be made into a photorealistic image, also called a rendering, or it can be used to produce a physical model prototype, usually through 3D printing.

The biggest advantages of using 3D CAD for jewelry design and manufacturing include a conceptual design, viewable from every angle, exacting measurements and dimensions, and a modifiable digital prototype that can be rebuilt or manipulated to show any color, size, or material.

While all 3D CAD for jewelry design programs are capable of the same basic creations, such as eternity bands, solitaire wedding rings, and pendant designs, there are some that specialize in certain aspects of jewelry making. Focusing on speed, precision, organic modeling, or relief sculpting, all necessitates a different design program. While there is no 3D CAD software that is good at everything, it is possible to combine the strengths of two different programs. As with 2D CAD files, 3D CAD files are also compatible with several different softwares, so a file can be created in one program and modified in another.

What CAD Can Do For You

Jewelry design and jewelry manufacturing has always been an exacting craft, yet now, you can create pieces that would otherwise be impossible using conventional manufacturing methods. From intricate latticework and minute details to jewelry that can be formed to the body, precision is the new standard.

Computer aided design also allows for complete customization to fit the needs of a jeweler’s client. Involving a client in the design is easier than ever, as now, a client can sit with a jeweler as they design a piece in real time.

Using CAD for jewelry design as a medium for creating more precise, custom pieces is becoming the trend everywhere as customers raise their expectations. Let MKM Jewelry elevate your jewelry design to excellence with 3D CAD software.

Leave a Comment