Three-dimensional design is an evolving process that is highly dependent on current technology. Though model making is an ancient jewelry and sculpting technique, it’s still used today due to its reliability and convenience. With the advent of new technology, such as 3D jewelry printing, model making has developed into an even more beneficial method for jewelers and sculptors to use.

The Process

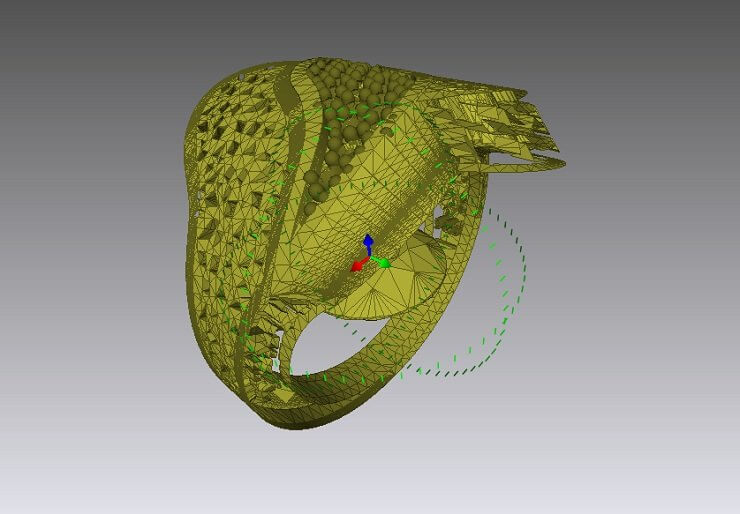

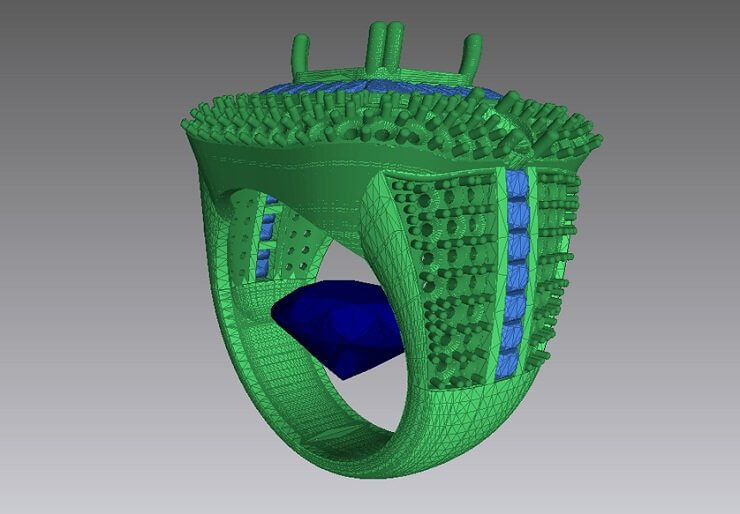

To create a three-dimensional model with a 3D printer, first a virtual design is required. Often, jewelry makers prefer to create a design on their own, working with computer aided design (CAD) programs specifically for jewelry. Some jewelers may entrust their vision to a manufacturer and allow them to interpret their designs.

Once a design has been approved, a manufacturer or jeweler sends the file to a printer for 3D jewelry printing. From there, the printer lays down layer after layer to fabricate the model in wax. The wax model is then perfected by the jeweler, and struts are added to brace the piece as it is prepared for molding. Intricate portions of the printed model may need to be recarved or detailed before it’s ready to create the mold.

Once the model is perfected, the lost wax process begins. A powder investment is mixed to create a cream that is poured around the wax model. The wax is then melted out over several hours in an oven. The empty space left by the wax is filled with precious metal to create the final piece. Subsequently, the struts are removed from the casting and the piece is finished and polished.

When an artist intends to create just one piece, sometimes cutting out the wax process and printing the jewelry directly in metal is a more efficient, though slightly more expensive choice.

The Benefits of Modern and Ancient Methods

Part of the reason 3D jewelry printing—also known as a computer aided manufacturing process—is making such an impact on the jewelry industry is its ability to integrate with modern techniques to ease the process of jewelry making. Printing wax models is especially significant, as the lost wax casting method is one of the most popular among jewelry makers.

Create Faster

When you print a model through 3D jewelry printing, as opposed to carving it by hand, the process can be considerably accelerated. In this way, jewelers can stay ahead of their competition and keep up with customer demands for popular pieces.

Designing on a computer also allows you to immediately observe any potential issues with the piece and modify it, reducing the trial and error process and decreasing the production time from several months to just a few days. These printers and programs are available to individual artists, as well as large businesses, leveling the field for independent artisans.

Cutting Costs

Creating prototypes by hand is undoubtedly expensive. Model tools and production runs are investments that consume both capital and precious time. When mistakes are made or the client doesn’t like the end result, it can be more costly to recreate the piece in several different sample runs.

3D jewelry printing allows for a far more streamlined process. Beyond the opportunity to see and modify a digital manifestation of the piece before printing, the 3D jewelry printing process allows parts and pieces to be made at a lower cost than traditional model and mold making.

Intricate Detail

While wax modelling by hand allows an artist complete creative control, modelling a piece in a 3D jewelry printing program enables many more options that simply aren’t possible when working by hand. A jeweler can execute delicate and intricate styles without posing any risks to the model.

For example, if an artist were to build a piece with intricate details intertwined or carved within the piece, they would be forced to solder multiple models together. With a 3D program and printer, these spliced designs are printed directly in wax without any soldering required.

A 3D computer aided design program even allows a jewelry maker to create a trial example of engraving or enameling.

Making Risk-Free Changes

It’s nearly impossible to build a new piece of jewelry without making a few changes. By 3D jewelry printing a model, a jeweler can verify their design before investing in an expensive process. It’s far more affordable to print a test prototype and redesign in CAD than to alter an existing mold.

Jewelers, Manufacturers, & Clients

Describing or drawing a piece of jewelry you plan on creating can often be misinterpreted by the clients or manufacturers. A jeweler always risks errors in manufacturing every time they design a new piece.

With a design fabricated in a computer-aided design program, there is no way to mistake the artist’s vision. Not only does a CAD program create a clear blueprint for the manufacturer, it can also render a conceptual picture that is more elaborate and clear than a drawing or description. In fact, with the low cost of printing an initial model, a client or artist can hold a physical prototype that is a close representation of the finished product.

Virtual Inventory

The cost of nearly every product and material can fluctuate according to global market demands. This creates a risk for any artisan who maintains a physical inventory, as shifts in the price of precious metals and gems can devalue inventory in minutes.

With the speed and affordability permitted by 3D jewelry printing, a jeweler can create a virtual inventory with a lead time of several days. Furthermore, an artist has more flexibility to display different variations of the same piece rendered in a CAD program, and the client can see several options before committing.

The Human Touch

While some may believe that 3D printers and CAD programs jeopardize the human touch of jewelry making techniques, personal inspiration and an artistic vision still play a dominant role in using CAD for jewelry making.

Artists supply the inspiration, design, and style behind every model created on the computer, and their talent to transform ideas into a reality is irreplaceable. Although manual labor is present during all stages, especially post-processing, it is essential to set stones or correct any irregularities left behind by the 3D jewelry printing.

MKM Jewelry’s Role

At MKM Jewelry, we supply an affordable platform for model and mold creation, allowing artists to streamline their processes. For those who are still unfamiliar with modern model making, MKM Jewelry has the professional skill sets necessary to recognize your vision and supply your business with the highest quality jewelry pieces. Contact us today to learn how we stay up-to-date on the newest jewelry making methods and techniques.

Leave a Comment