CAD (Computer Aided Design) and

CAM (Computer Aided Manufacturing) are revolutionizing industries across the world. For several years, this cutting edge technology has begun to be used in the jewelry industry. As new techniques are developed, jewelry manufacturing has been pushed to new levels of innovation. Learn more about CAD and CAM when you read on today.

What Exactly is CAD and CAM?

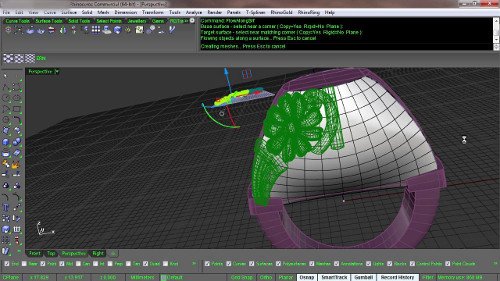

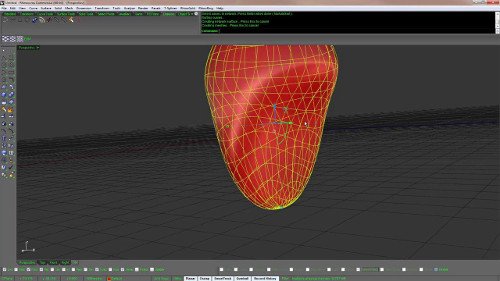

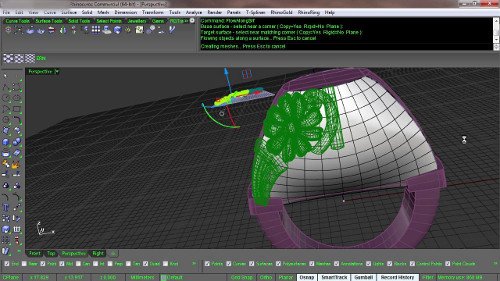

CAD is an abbreviation for Computer Aided Design, which is a process that uses computer systems to create, modify, analyze, and optimize designs. CAD can be used to design both two-dimensional and three-dimensional objects. Using computer software, designers can draft shapes and forms digitally, instead of on paper. Due to computer modelling, CAD allows for a much greater depth of information than traditional drafting. CAD models also communicate information about materials, processes, and dimensions; data that is critical for manufacturing.

Designers use CAD in manufacturing because it dramatically streamlines the design process. CAD software allows designers to be more productive, communicate more information, and easily create new iterations of the same design. It also gives them greater precision in the design process.

Benefits of CAM

After a product is modeled with CAD, it is fabricated using CAM technology. Computer aided manufacturing, commonly referred to as CAM, is a type of software used to control machine tools in manufacturing. Computer aided manufacturing uses computers to assist in many parts of the production process, including planning, management, transportation, and storage. By using CAD in manufacturing to automate production, manufacturing processes can be more precise, consistent, and efficient than traditional methods.

How is CAD in Manufacturing Used for Jewelry?

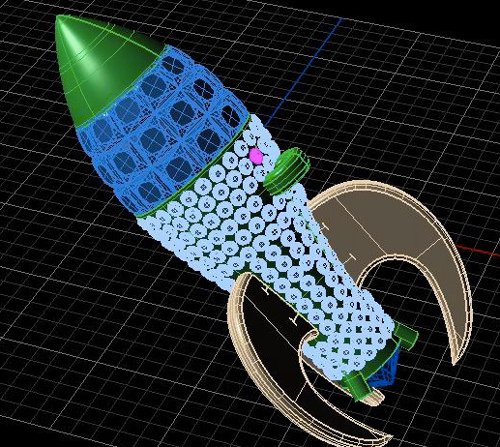

CAD has been used for many years in architecture and industrial design. However, jewelry manufacturers have also been jumping on board this tech revolution. CAD software has allowed jewelry designers to attempt much more complex designs and truly push the limits of jewelry fabrication. It has also opened the door for client customization in jewelry.

New 3D Printing Technology in Jewelry

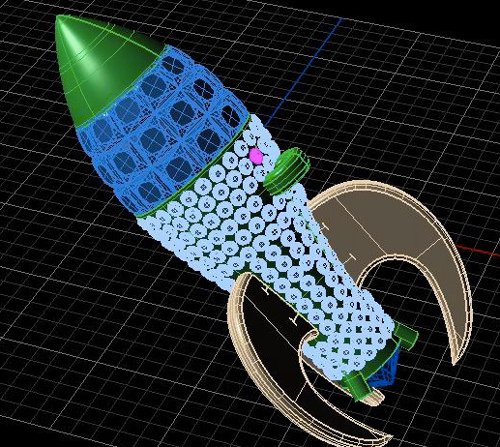

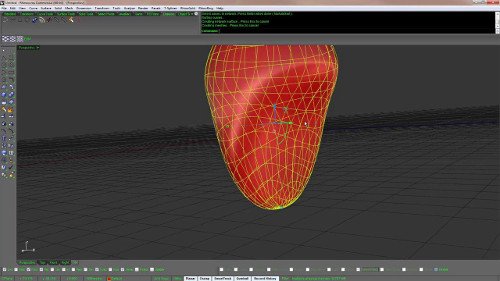

Traditionally, many jewelry pieces were fabricated with lost wax casting, which involved making molds of hand carved wax models and casting them into precious metals. The intricacy of these original pieces was limited by the dexterity of the artisan carving the initial wax model. However, with the advent of CAD in manufacturing, a new level of detail can be achieved in lost wax casting. Jewelry designers can 3D model their designs using CAD software and then use new 3D printing technology to print the digital models into wax, eliminating the hand carving process.

Some jewelers are eliminating the wax casting altogether and are experimenting with 3D printing gold and platinum directly. 3D printing metal is a cutting edge technique that is still developing, but is sure to open up a world of possibility for jewelry designers.

These new 3D printing technologies can also be used for more unconventional materials. Less traditional jewelry designers are experimenting with using 3D printing to make jewelry out of hard plastics, ceramics, and other materials.

Full Customization with CAD

As the traditional files, anvils, and saws of a jeweler’s craft have slowly been replaced by the computer mouse and monitor, designing jewelry has become more accessible to those lacking a rigorous craft background. While designing fine jewelry with CAD technology takes no less artistry and skill than forging pieces by hand in a metalsmith workshop, digital fabrication allows clients to enter the process in ways that were never before possible.

With Computer Aided Design, jewelry designers can easily create dozens of similar iterations with a few clicks of the mouse. Instead of handcrafting prototypes out of metal and wax, jewelers can draft digital models to show to clients. Because tweaking digital designs is so much cheaper and less labor intensive than traditional jewelry fabrication, CAD allows for greater collaboration between clients and jewelers.

Some jewelers are even letting clients take the jewelry design process into their own hands. A few jewelry companies have begun creating web interfaces that allow customers to mix and match different designs to create the custom piece of their dreams.

CAD in Manufacturing as a Marketing Approach

While some customers still seek out handmade, artisan jewelry lines, CAD modeling for jewelry is becoming highly desirable, especially for younger customers in their 20s and 30s.

CAD modeling is particularly popular in the engagement ring market. Customers want their engagement rings to be completely unique; a fully customized representation of their singular love. CAD in manufacturing allows couples to customize their own engagement rings.

To a younger, tech-friendly customer base, CAD in manufacturing and 3D printing is a new type of bespoke jewelry. Fine jewelers are marketing CAD jewelry as a flexible way to design beautiful, heirloom quality pieces. Although the technology may be cutting edge, the final pieces are just as durable and timeless as traditionally produced jewelry.

Experts in CAD and CAM

CAD in manufacturing is paving the way for a new era of jewelry design. More and more, jewelry designers are choosing CAD to create detailed, intricate pieces that push the boundaries of jewelry design. If you’re thinking of

entering the digital design and manufacturing world, reach out to the experts at MKM Jewelry to find a knowledgeable team that can help you design and create your own line today. Whether you’re focused on fashion jewelry or fine jewelry, we can help you use CAD in manufacturing to bring your vision to life.

Get started

here!

Leave a Comment